Ceramic Beads

Made by special way,the density is higher

Made by special material of 95% Granular powder,in this way,the heat treatment is better

Precise Mold control so that the tolerance is strict

Technical data

Density 3.65g/cm3

Alumina content 95%

Hardness(Mohs) 9

Rockwell hardness(HRA) over 75

Compression strength : 2000 MPa

Safety working temperatures : over 1500

Water Absorption rate : 0.01%

Thermal Conductivity 24 W/mK

Flexural Strength 340 Mpa

Properties: High density, good apprearance and high alumina content, excellent thermal condictivity and heat transfer, resistance against thermal shock and mechanical abuse.

Application:This special sintered alumina ceramic beads as components of ceramic pad and channel heaters can be used for pre and post-heaters welding applications because of its excellent heat resistance.

All flexible ceramic pad heaters are constructed of 80/20 Nickel/Chrome multi-strand wire, insulated with interlocking sintered alumina pink ceramic beads, nickel cold tail wire, and two Male Camlocks.

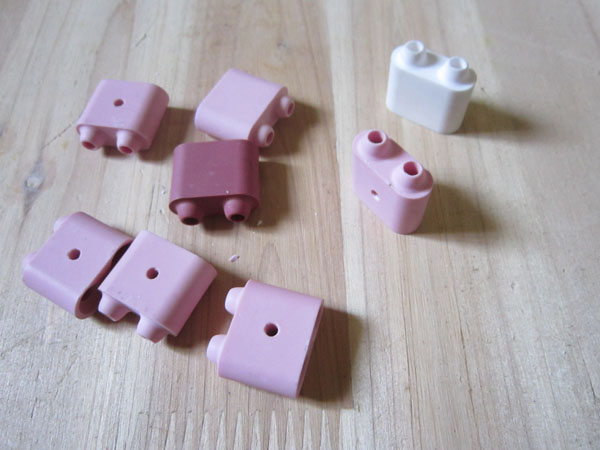

Ceramic beads ( by dry press, in pink or white)

*Main body bead

*Main body bead with hole

*Male end bead

*Female end bead

*Tail bead

ceramic beads

alumina ceramic beads